Avec la transition vers des solutions de mobilité bas-carbone, le choix des batteries joue un rôle essentiel dans l’avenir des véhicules électriques. Les batteries LFP (Lithium Fer Phosphate) et NMC (Nickel Manganèse Cobalt), dénommées toutes les deux par la composition de leur cathode, sont deux des principales technologies Lithium-Ion sur le marché, chacune avec ses avantages et inconvénients. Comprendre leurs différences permet d’identifier la meilleure solution en fonction des besoins de chaque application.

LFP Batteries: A Sustainable and Safe Technology

To return to the origins of LFP batteries., trois brevets majeurs concernant cette technologie ont été déposés il y a plus de 20 ans. Le premier a été publié par le père des batteries au lithium-ion, l’Américain et prix Nobel de chimie, John B. Goodenough, along with his team at the University of Texas in 1997, who notably identified lithium iron phosphate (LiFePO4) as a cathode for lithium-ion batteries. Two other patents were filed in the 2000s by Hydro-Québec and the CNRS to enhance the conductivity and production of this battery's cathode. These global patents were offered for licensing by the company LiFePO4+C, a consortium including the University of Montreal, Hydro-Québec, CNRS, and Johnson Matthey.

This technology was ultimately abandoned by Western countries, South Korea, and Japan in favor of NMC, which offers a higher energy density (about 175 Wh/kg for LFP compared to 245 Wh/kg for NMC). At the same time, Chinese players, financially supported by their government, were the only ones to continue improving LFP, initially for the domestic market. LFP is now making a strong comeback globally, thanks to its significant advantages: its cost allows for more affordable entry-level electric vehicles, and its lifespan meets the needs of high-value industrial vehicles.

The LFP batteries are particularly recognized for their safety and longevity, largely due to their chemistry. Using lithium iron phosphate, phosphate de fer lithié (LiFePO4) for the cathode, they exhibit greater thermal stability than other lithium-ion batteries. Their critical temperature, at which self-heating begins, is significantly higher. This thermal stability arises from the specific chemistry of LFP, which does not release oxygen in the event of thermal runaway, thereby significantly reducing the risk of fire.

According to a report sur la transition énergétique et les mobilités bas-carbone publié par le Commissariat général au développement durable (CGDD), les batteries LFP sont à privilégier pour les véhicules électriques en raison de leur durée de vie importante (environ 4000 cycles) et de leur impact environnemental moindre. Le rapport met en lumière que ces batteries, dépourvues de métaux rares comme le cobalt ou le nickel, sont non seulement plus sûres mais également plus respectueuses de l’environnement, favorisant une économie circulaire plus robuste dans le secteur des batteries.

Les batteries LFP sont ainsi moins sujets à la volatilité des prix et aux risques d’approvisionnement des métaux comme le cobalt et le nickel et leur coût est moins élevée que le NMC.

This battery technology, relatively unknown a few years ago, is particularly well-suited for industrial vehicles that require a long lifespan with a low power-to-energy ratio. It is also a very attractive option for mid-range vehicles where the priority is placed on cost rather than range.

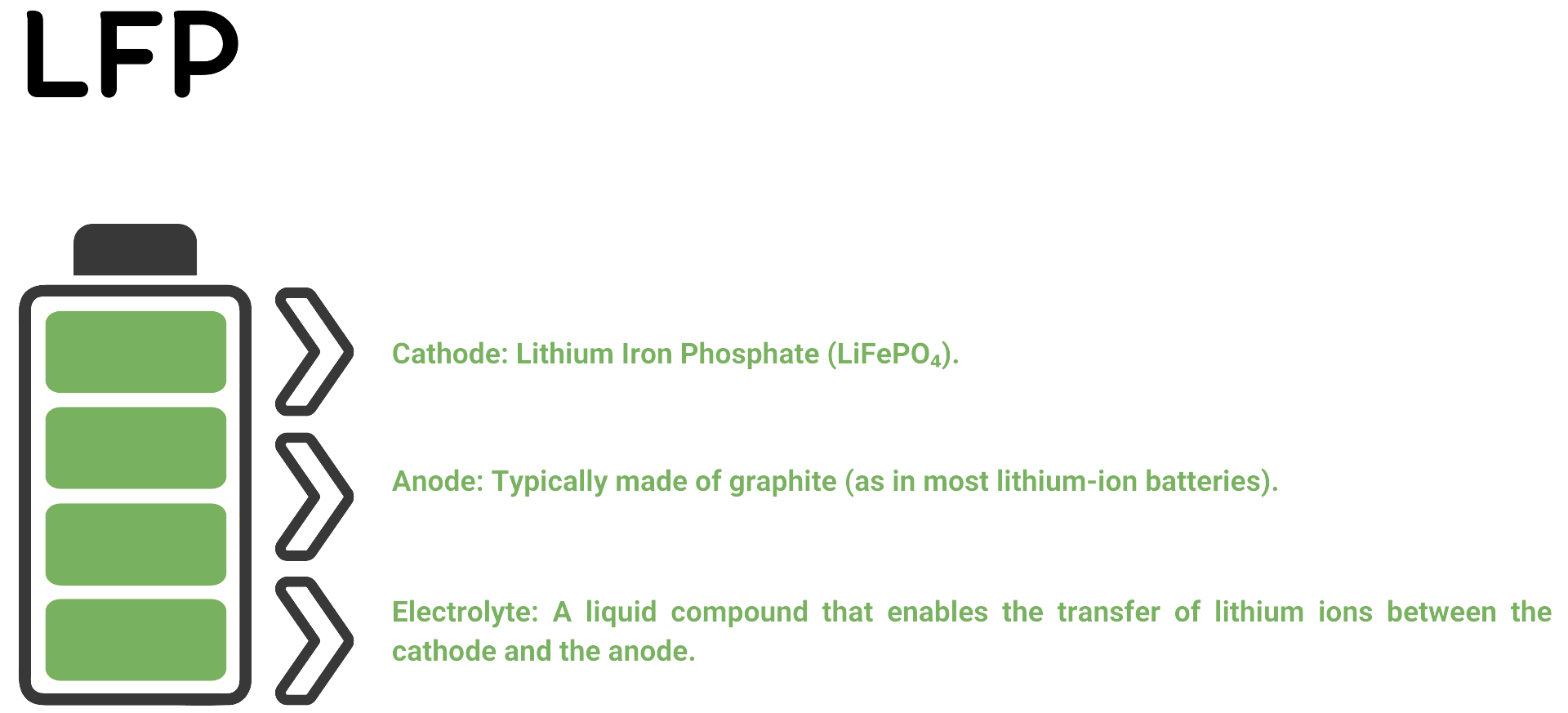

Key Components:

What are the technical characteristics of LFP batteries?

- Energy Density: Around 175 Wh/kg at the cell level.

- Voltage Range : 2V or 2.5V up to 3.65V at the cell level.

- Operating Temperature : From –20°C to 65°C during discharge; charging should be done at a temperature above 0°C.

The voltage of the LFP cell varies very little between 10% and 90% state of charge (SoC), which poses a real challenge for electronics to accurately estimate its SoC. For this reason, it is often recommended to fully charge the LFP battery regularly to avoid calculation errors and to better calibrate the state of charge.

What are the advantages of LFP batteries?

- Increased Safety : Compared to other lithium-ion batteries (such as NMC), LFP batteries are less likely to overheat or cause fires. They are preferred in high-risk applications, such as in airport settings.

- Long Lifespan : They have a longer lifespan, with a greater number of charge-discharge cycles (around 4,000 cycles).

- Thermal Stability : LFP batteries are more thermally stable, making them suitable for high-temperature environments or for simpler designs without the need for liquid cooling, for example.

- Eco-friendly : The absence of rare metals such as cobalt or nickel makes them more environmentally friendly.

What are the applications of LFP batteries?

- Electric Vehicles : LFP batteries are widely used in electric vehicles in China, such as BYD, and are starting to be used in Europe, like the Tesla Model 3.

- Industrial vehicles : They are increasingly used in industrial vehicles that require a long lifespan without needing a high energy density.

If you are interested in our LFP battery packs or have any questions, please feel free to contact us. here !

NMC Batteries: A Premium Technology Designed for Performance

NMC batteries (Nickel Manganese Cobalt) are widely used in electric vehicles due to their high energy density. They allow for more energy storage in a smaller space, providing better range for vehicles.

According to a report from the CARA competitiveness cluster, NMC batteries will increasingly become the choice for high-end electric vehicles. Their performance is significantly superior in terms of energy density and power density, although this comes at the cost of thermal stability, necessitating the installation of increasingly complex and expensive cooling systems, such as immersion cooling. NMC cells also have a higher cost due to reliance on materials like cobalt.

The challenge now is to reduce the amount of cobalt in NMC batteries. while, in turn, increasing the nickel content, which raises the thermal instability of the battery.

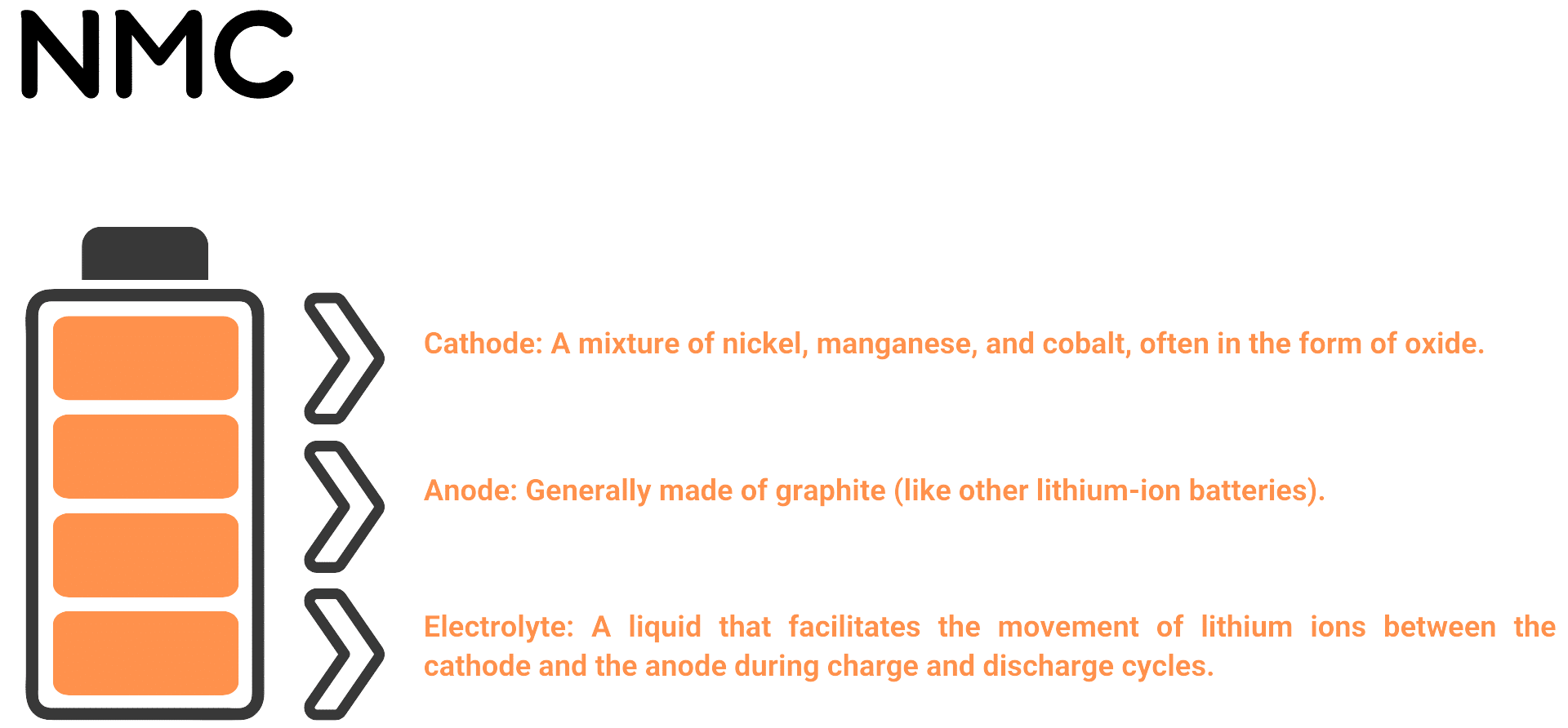

Key Components:

What are the technical characteristics of NMC batteries?

- Energy Density: Around 245 Wh/kg at the cell level.

- Voltage Range : 2.75V to 4.35V at the cell level.

- Operating Temperature : From –20°C to 55°C during discharge; charging should be done at a temperature above 0°C.

Unlike LFP batteries, the voltage of NMC cells varies steadily with the state of charge (SoC), making it easier for electronics to estimate the charge level. Conversely, when the battery discharges, the overall voltage decreases, requiring the current to increase to maintain the same power level.

What are the advantages of NMC batteries?

- High Energy Density : NMC batteries can store a large amount of energy for a given weight or volume, making them ideal for applications requiring high range.

- Good Balance Between Power and Capacity : They provide a good compromise between power (the ability to deliver energy quickly) and capacity (the total amount of energy stored).

Applications of NMC Batteries

- Electric Vehicles : It is one of the most commonly used batteries in the automotive industry due to its energy density, which allows for high range.

- Automotive Competition: thanks to its high power density and increasingly advanced cooling systems, it is the preferred chemistry for automotive competition.

NMC Batteries: A Balance Between Power and Energy Density

For professional and industrial vehicles requiring a long lifespan, NMC batteries are often the preferred choice. LFP batteries provide a robust, durable, and more affordable solution. However, NMC batteries are preferred in segments requiring high performance and greater range, such as premium electric vehicles.

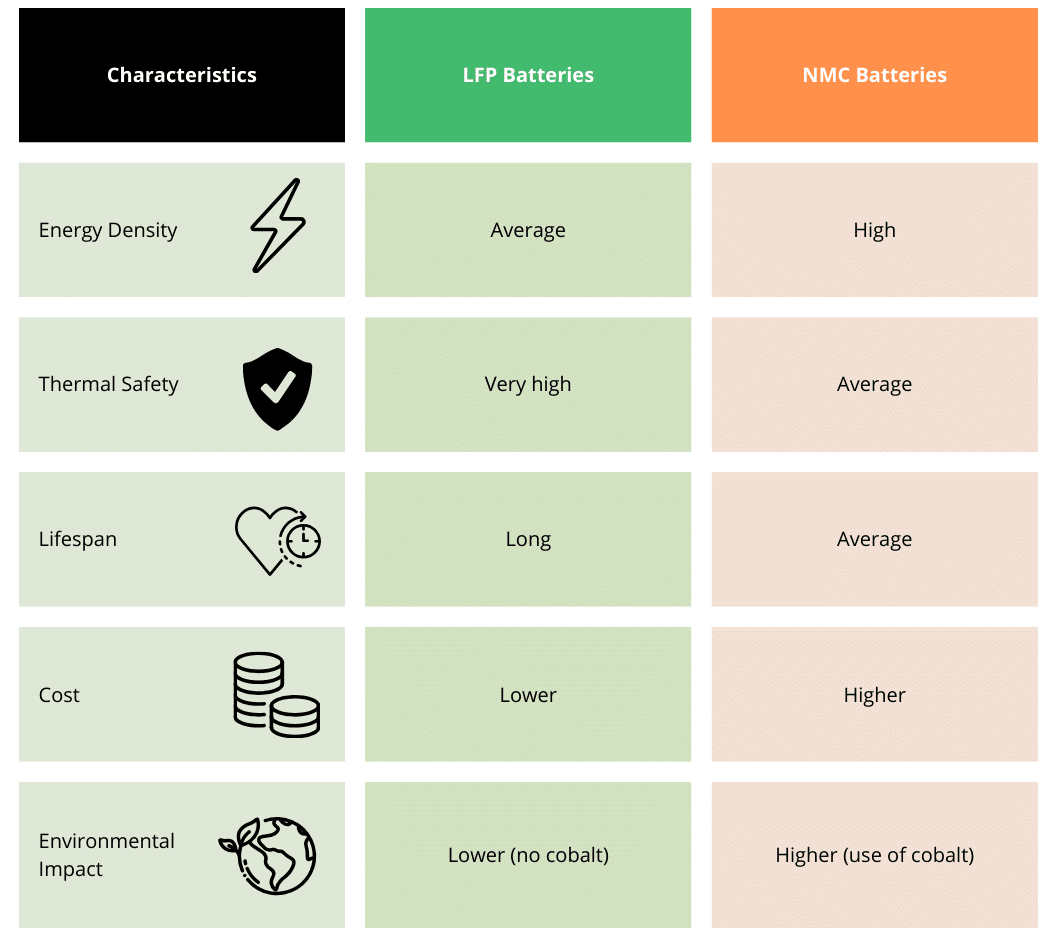

Comparative Table:

LFP and NMC batteries represent complementary solutions in the transition to more sustainable mobility. The choice between these two technologies will largely depend on the priorities of each project, whether it be safety, range, or cost. While LFP batteries position themselves as a more eco-friendly and secure solution, NMC batteries dominate applications requiring maximum performance.

If you are interested in our LFP battery packs or have any questions, please feel free to contact us. here !